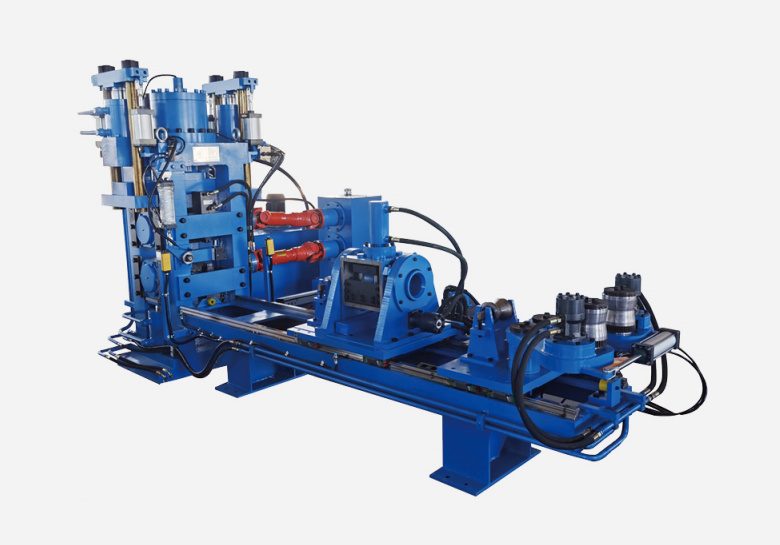

Cnc Hydraulic Flattening Machine

The CNC hydraulic flattening machine is used to flatten the both ends of spring bars. it can control the flattening length, fattening taper, flattening width, and flattening thickness, it can realize fully automated production from heating to fattening.

Key words:

Classification:

Email:sxjkzdh@163.com

Detailed introduction

Graphic Details

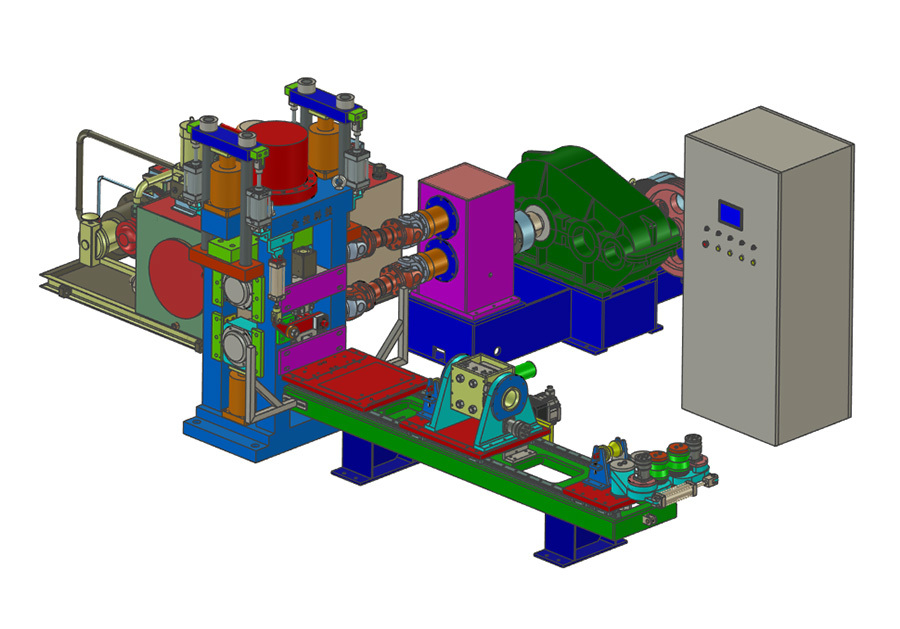

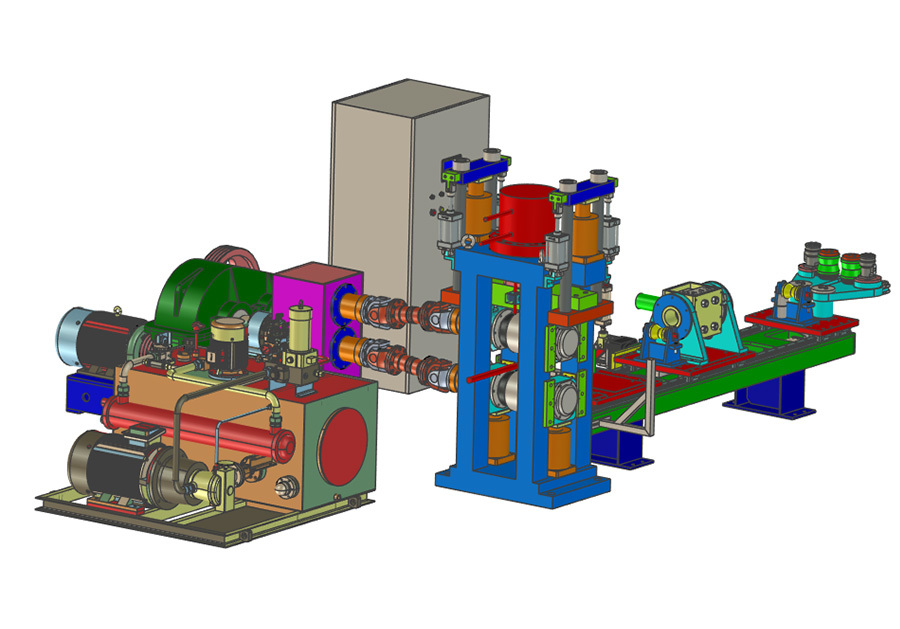

Equipment Introduction

The CNC hydraulic flattening machine is used to flatten the both ends of spring bars. it can control the flattening length, fattening taper, flattening width, and flattening thickness, it can realize fully automated production from heating to fattening. in the flattening process, the hydraulic partial fiow is used to control the operating speed of the oil cylinder to control the lowering speed of the roller, thereby producing the material taper required by the user. The upper and lower rollers can operate synchronously and symmetrically to ensure that the material is not easily defomed and bent during the production process. lt can automatically complete clamping, feeding, positioning, clamping, turning, feeding, fattening, marking, exit, blanking, buffering and other actions.

Functional Advantages

Servo Motor Control

The servo motor controls the initial position, feeding position, positioning position, marking position, exit position, etc. of the material. Different positions for each feed can be set to achieve step-by-step feed.

Material receiving rack and blanking rack

Responsible for feeding heated materials into the equipment, which can be raised and lowered, and move flattened materials into the blanking rack. Materials with different wire diameters can be adjusted to the same center line.

Upper and Lower Rollers Use Hydraulic

The upper and lower rollers operate synchronously by using hydraulic means, which has good synchronization effect and avoids precision errors caused by two-way control. Hydraulic transmission ensures uniform force on the upper and lower parts and synchronized operation.

Marking

After the rolling is completed, the material is controlled to the set position, and the marking cylinder moves up and down synchronously for marking. The angle of the marking head can be automatically adjusted according to the taper of the material.

Specification Parameters

| Equipment Model | ZYD-80 only makes one model |

| Total power | 65kw |

| Roll motor | 30kw |

| Hydraulic motor | 30kw |

| Feed servo motor | 3kw |

| Roll speed | 18r/min |

| System traffic | 80L/min |

| System pressure | 20MPa |

| Flat material diameter | 20-80mm |

| Maximum flat-making length | 1200mm |

| Flat-made temperature | 950℃~1000℃+10℃ |

| Material length | 2800mm-10000mm |

Previous:

Related Products

Graphic Details

Product Consulting

Graphic Details