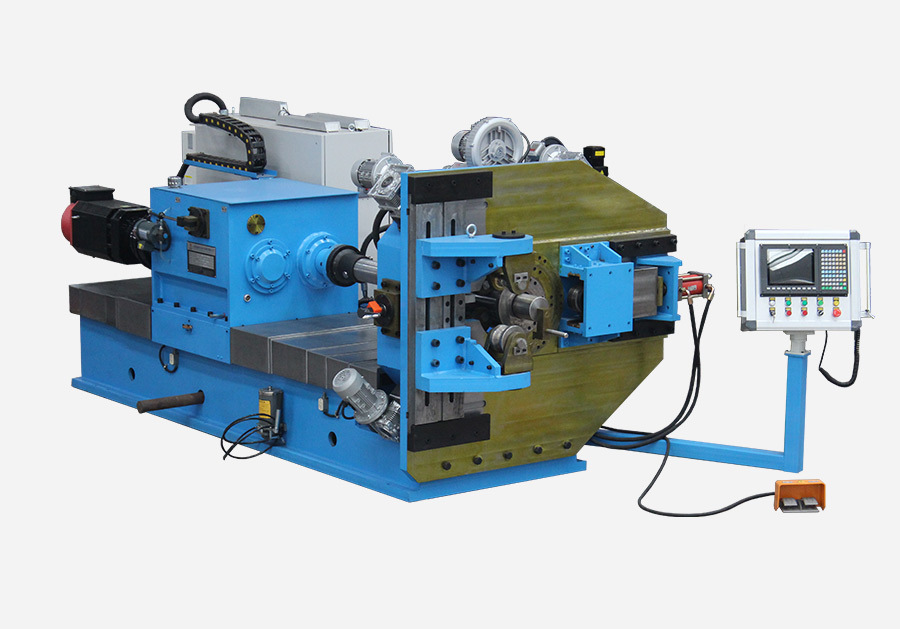

Two-Axis Cnc Hot Spring Coiling Machine

The two-axis CNC hot spring coiling machine is used for roling various types of springs. it has many equipment models and can produce a wide range of springs. lt can produce wire diameters of 20-100mm, outer diameters of 100-700mm and heights of 150-2000mm.

Key words:

Classification:

Email:sxjkzdh@163.com

Detailed introduction

Graphic Details

Equipment Introduction

The two-axis CNC hot spring coiling machine is used for roling various types of springs. it has many equipment models and can produce a wide range of springs. lt can produce wire diameters of 20-100mm, outer diameters of 100-700mm and heights of 150-2000mm. it can also be customized to produce larger size equipment. Using the CNC control system and two sets of servo motors to control the number of rolling tums and pitch respectively. The roling speed can be controlled to be continuously variable within the rated speed, and the mandrel can be controlled to advance and retreat in order to achieve functions such as pitch change, doubling, closing, and spring withdrawal. G code programming is simple, fiexible and the process control of production is diverse, users can program and design by themselves, and it can produce cylindrical spiral springs, torsion springs and other special-shaped springs of any specifications. The equipment is cost-effective and suitable for spring production users with small batches, many specifications and medium requirements.

Functional Advantages

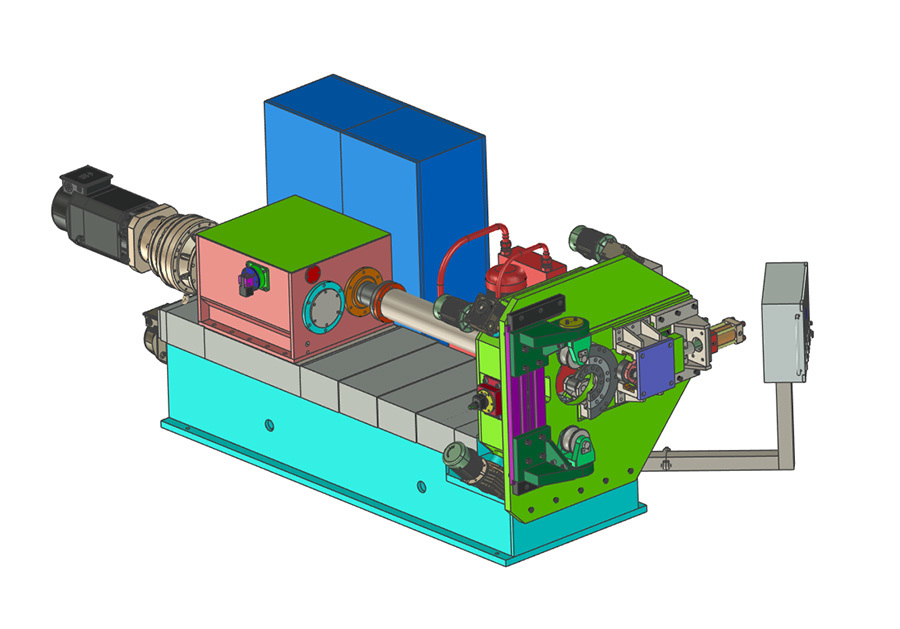

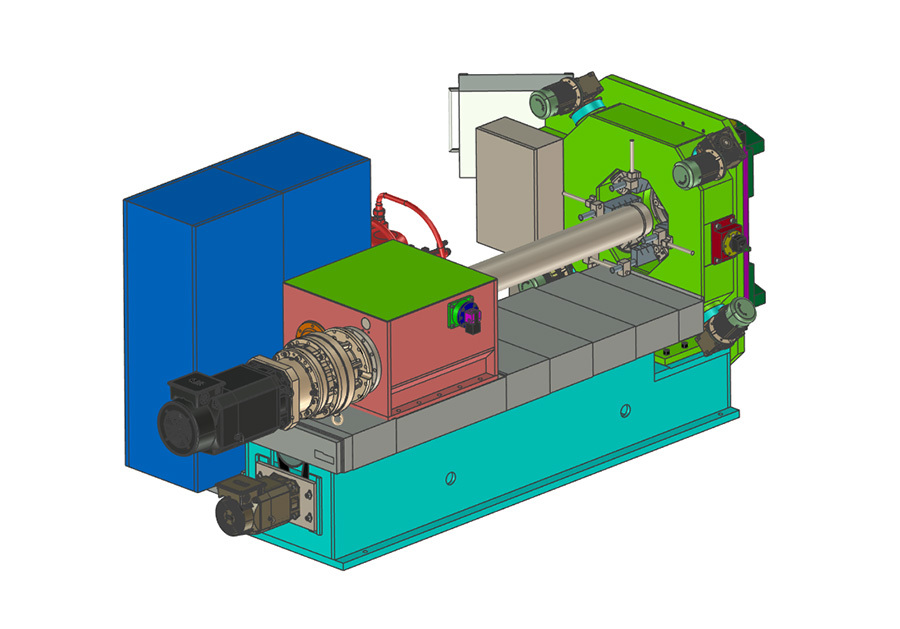

Spindle Box

The spindle box can switch between fast gear and full gear, which can simultaneously meet the needs of fast rolling speed of small wire diameter springs and high torque of large wire diameter springs.

Feeding Wheel

The feeding wheel can be adjusted forward and backward through the handle with a scale, and it can be adjusted up and down and rotated at a fixed angle or freely rotated within a certain angle range.

Finishing Device

The position of the closing device can be adjusted through the handle with a scale. The closing wheel and the spring unloading plate cooperate with each other to complete the closing, spring unwinding and other processes. lt is more suitable for rolling springs with flattened ends.

Core Rod Center Frame

The center frame of the mandrel is composed of four sets of electrically retractable roller, swhich can be retracted at the same time or run independently to support the mandrel.

Specification Parameters

| Equipment Model | SXJ-50 | SXJ-65 | SXJ-80 | SXJ-100 | |

| Rolling material diameter range | 20-50mm | 20-65mm | 20-60mm | 20-100mm | |

| Mandrel outer diameter range | 60-250mm | 70-350mm | 80-450mm | 150-500mm | |

| Spring height range | 150-800mm | 150-1200mm | 200-1600mm | 300-2000mm | |

| Spring outer diameter range | 100-350mm | 110-480mm | 120-600mm | 220-700mm | |

| Maximum spring weight | 200kg | 250kg | 350kg | 500kg | |

| Rolling material diameter range | 40kw | 55kw | 65kw | 80kw | |

| Spindle speed | Fast gear | 73r/min | 65r/min | 53r/min | 45r/min |

| Slow gear | 30r/min | 27r/min | 21r/min | 18r/min | |

| Spindle box guide rail | 55mm | 65mm | 65mm | 85mm | |

| Equipment weight | 7t | 9t | 11t | 15t | |

Related Products

Graphic Details

Product Consulting

Graphic Details