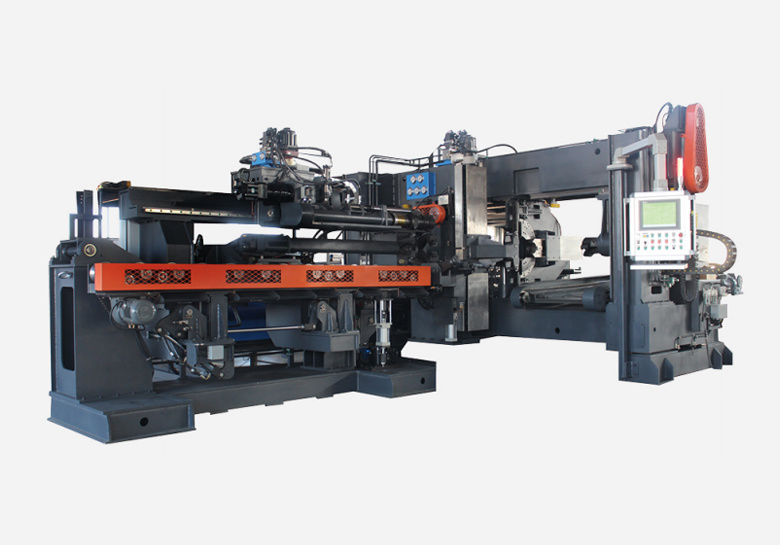

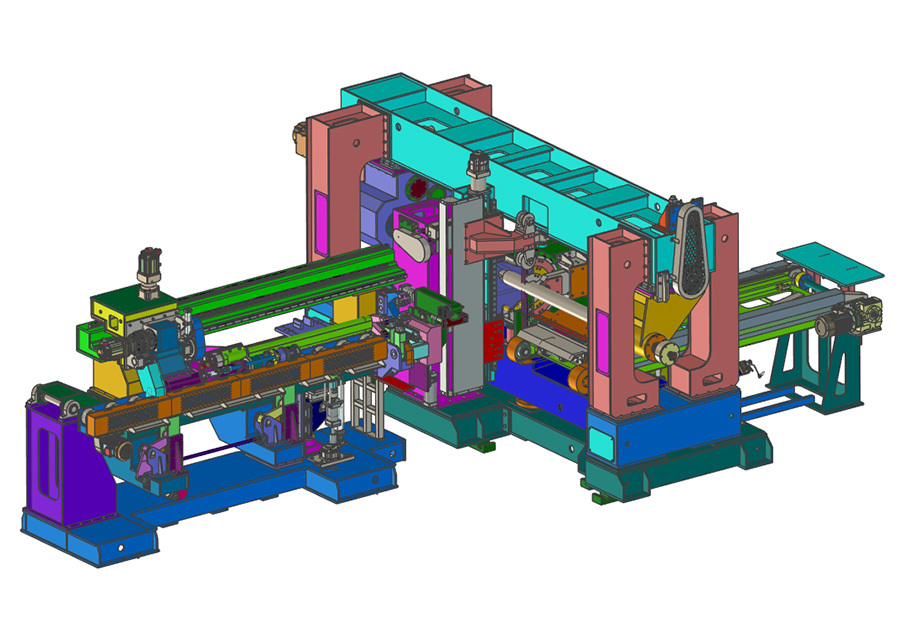

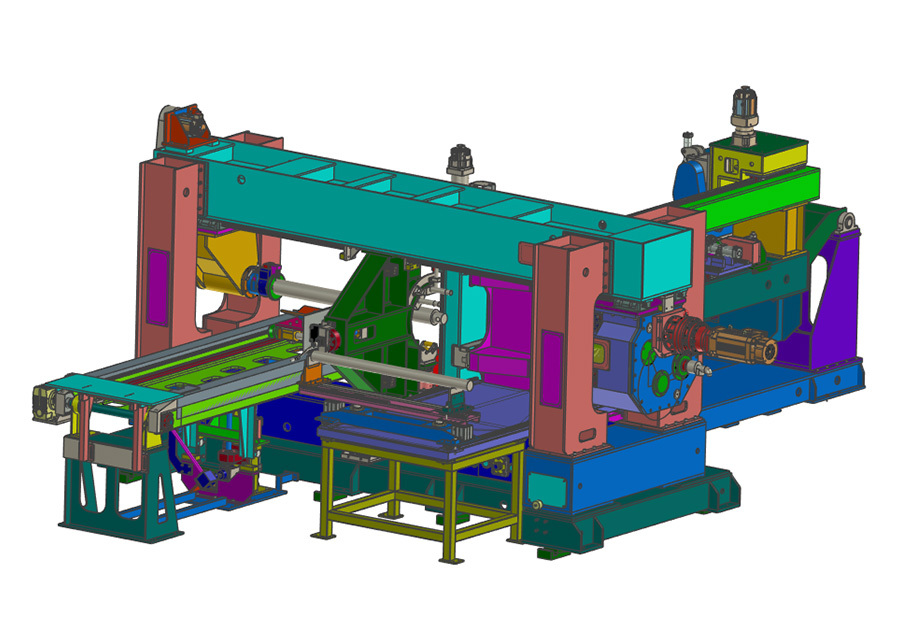

Ten-Axis Fully Automatic Hot Spring Coiling Machine

The fully automatic spring coiling machine is suitable for thermoforming processing of various forms of cylindrical helical springs. This spring coling machine can realize multi-axis linkage rolling and meet the roling requirements of high-precision springs.

Key words:

Classification:

Email:sxjkzdh@163.com

Detailed introduction

Graphic Details

Device Introduction

The fully automatic spring coiling machine is suitable for thermoforming processing of various forms of cylindrical helical springs. This spring coling machine can realize multi-axis linkage rolling and meet the roling requirements of high-precision springs. lt has the characteristics of high eficiency, stable product quality, high degree of automation, simple operation, high reliability and safety, and it can realize fully automated production. The equipment is equipped with a mandrel cooling device, a mandrel replacement device, a spring device, a body swing device, a feeding angle lifting device, etc. lt also has hydraulic clamping, material positioning, end marking, end face leveling, mandrel extension and contraction, and spindle functions such as qear shifting and mandrel support. it can realize automatic feeding, rolling, tailing, spring withdrawal, spring connection, and unmanned operation on site.

Functional Advantages

Body Swing

The system can control the swing of the equipment bed, with a swing angle range of 0-10°, Meeting the requirements for the helix angle of the helical spring.

Automatic Tail-handling

The tail-handling device controls the feeding angle and hydraulic locking of the material tail, the servo motor controls the rotation, and the tail-handling feeding device cooperates with the rolling part to operate in overal linkage.

Automatic Feeding

The heated material can be sent out and rotated to the feeding angle, and the marking position and feeding position of the materia can be controlled.

Remote Diagnosis

There is a remote diagnosis service function, which can be connected to the Intemet or use a mobile phone with 4G card for remote diagnosis, remote program modification or emergency maintenance.

Specification Parameters

| Equipment Model | JKSJ-50 | JKSJ-80 |

| Spindle speed range | 0~110 rpm | 0~112 rpm |

| Coil spring height | 150-800 mm | 150-1200 mm |

| Outer diameter of spring | 90-450mm | 120-600mm |

| Material diameter | 20-50mm | 20-80mm |

| Mandrel outer diameter range | 50-350mm | 60-450mm |

| Coil spring weight | 10-100KG | 10-350KG |

| Equipment weight | 28t | 38t |

| Installed capacity | 120 Kw | 150 Kw |

Related Products

Graphic Details

Product Consulting

Graphic Details