Numerical Control Hydraulic Flattening Production Line

The CNC hydraulic flatting production line is a set of efficient preprocessing equipment specifically designed for the spring manufacturing industry. It is mainly used for the flatting and forming of the ends of the bar material before spring coiling, achieving high-precision conical surface rolling of the metal bar ends. It can flexibly adjust the flatting thickness, width, length, and taper parameters to meet the process requirements for producing springs of different specifications. The equipment integrates automation, high precision, and high stability, significantly improving the preprocessing efficiency of bar materials, making it a core piece of equipment in the spring manufacturing production line.

Key words:

Classification:

Email:sxjkzdh@163.com

Detailed introduction

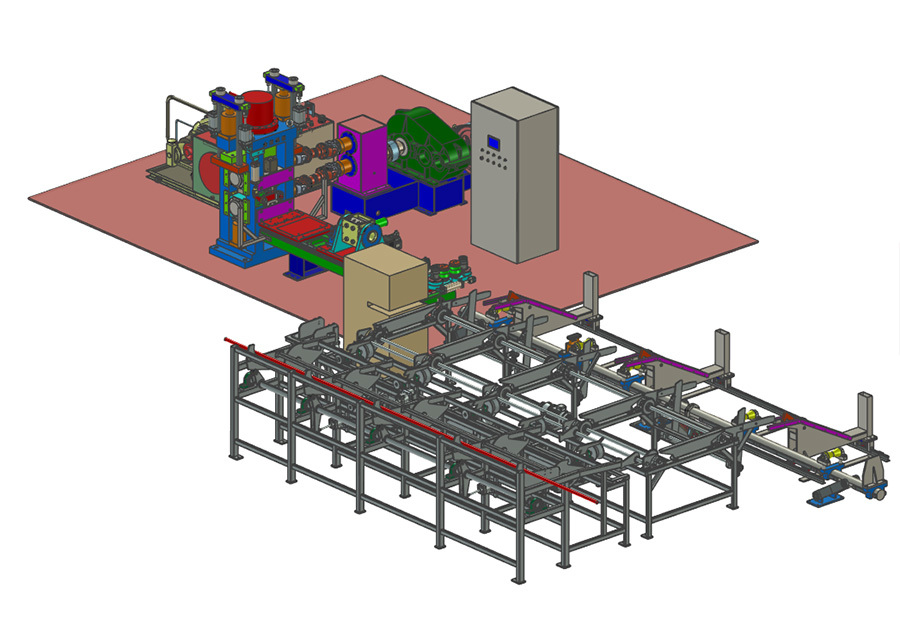

Graphic Details

Product Overview

The CNC hydraulic flattening production line is a set of efficient preprocessing equipment specifically designed for the spring manufacturing industry. It is mainly used for flattening the ends of raw materials before spring coiling, achieving high-precision conical surface rolling of metal rods. The thickness, width, length, and taper parameters can be flexibly adjusted to meet the process requirements for producing springs of different specifications. The equipment integrates automation, high precision, and high stability, significantly improving the preprocessing efficiency of raw materials, making it a core piece of equipment in the spring manufacturing production line.

Core Technical Features

Synchronous symmetrical roller structure, precise control of taper

The equipment features a symmetrically arranged upper and lower roller assembly, ensuring that the material does not easily deform or bend during production, thereby maintaining the symmetry and consistency of the conical surface formation at the ends of the rods. During the rolling process, the upper and lower rollers rotate synchronously in opposite directions, in conjunction with a hydraulic or servo drive system that precisely controls the pressure. The maximum flattening length can reach 1200mm, accommodating metal rods with diameters ranging from φ20 to φ80mm.

Modular mold design, flexible adaptation to processes

Equipped with a replaceable mold system, users can quickly switch between different specifications of products through rapid mold change. The molds are made of high-alloy steel, treated with heat treatment and surface hardening processes, improving wear resistance by over 50%, with a service life exceeding 100,000 times. Combined with a digital control system, multiple sets of process parameters (such as rolling speed, pressure, stroke) can be preset and called with one click, reducing manual intervention.

Efficient automated integration

Automatic heating feeding rack, flattening lifting device, CNC hydraulic flattening feeding section, and seamless linkage of the drop rack form a complete production line. The CNC hydraulic flattening feeding section achieves millimeter-level positioning accuracy through servo drive, accurately feeding the heated rods into the roller area, while the flipping mechanism simultaneously flips to complete the flattening in width and height directions at the ends of the rods. After rolling, the finished products are automatically collected by the drop rack, requiring no manual operation throughout the process.

Intelligent control and safety protection

Equipped with a PLC+HMI intelligent control system, it monitors rolling pressure, temperature, displacement, and other parameters in real-time, with automatic alarms and shutdowns for abnormal conditions. The equipment is configured with multiple safety protection devices, including emergency stop buttons, mechanical limit locks, overload protection, etc., ensuring operational safety.

Applications

Widely applicable to the preprocessing of rod ends for automotive suspension springs, industrial valve springs, large springs for construction machinery, etc., helping enterprises achieve standardized and large-scale production.

The CNC hydraulic flattening production line focuses on technological innovation, promoting the spring manufacturing industry towards intelligent and efficient upgrades, making it an ideal choice for improving product quality and competitiveness.

Previous:

Next:

Related Products

Graphic Details

Product Consulting

Graphic Details