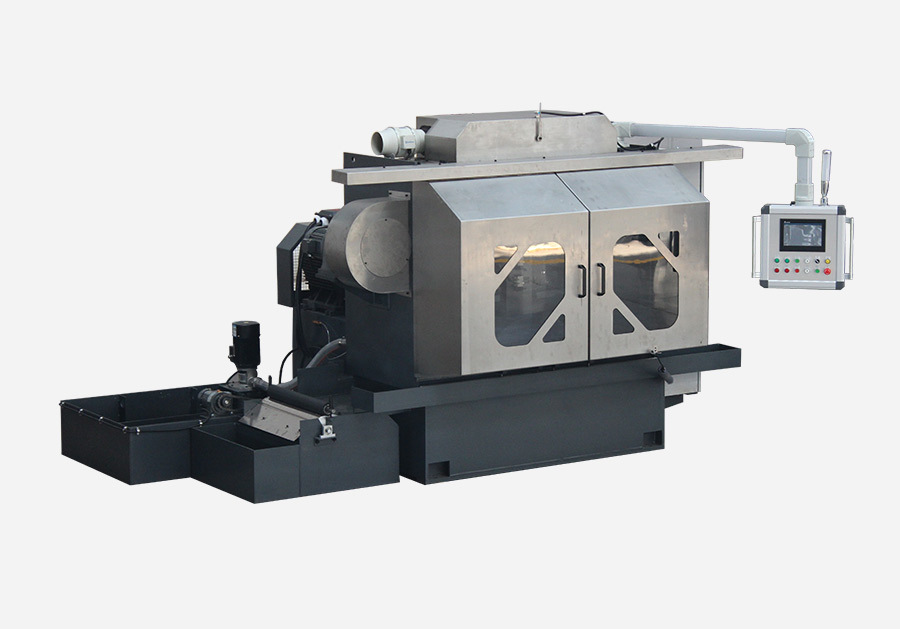

Cnc Double-Station Spring Grinding Machine

The CNC double-station spring grinding machine is mainly used for grinding spring end surfaces to ensure the verticality and flatness of the springs. The method of hanging and swinging on a spring, and the motor grinding wheel is fed from the rear, which can reduce the wear of the track and increase the life of the equipment and reduce the erosion of the track by sand and water.

Key words:

Classification:

Email:sxjkzdh@163.com

Detailed introduction

Graphic Details

Equipment Introduction

The CNC double-station spring grinding machine is mainly used for grinding spring end surfaces to ensure the verticality and flatness of the springs. The method of hanging and swinging on a spring, and the motor grinding wheel is fed from the rear, which can reduce the wear of the track and increase the life of the equipment and reduce the erosion of the track by sand and water. PLC can set the feed rate, feed speed and feed intensity of rough grinding and fine grinding respectively. The correction time after the feed also can be set by it. The screen can display the current value, correction time, working time, feed rate, and consumption compensation of grinding wheel, etc.

Functional Advantages

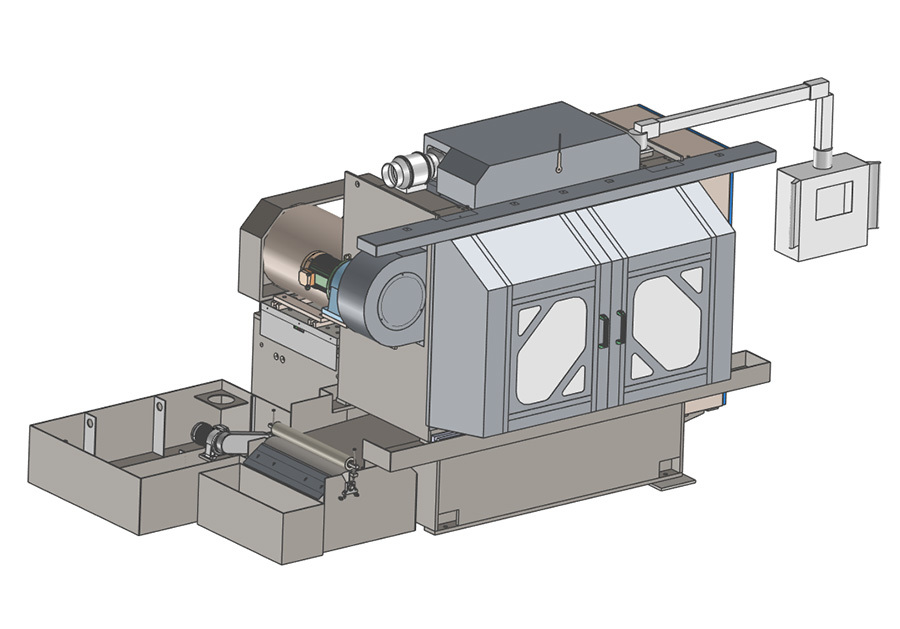

New Protection

The equipment adopts new overall protection. Stainless steel sliding door is used on the front to prevent the risk of grinding wheel breakage and water mist splashing.

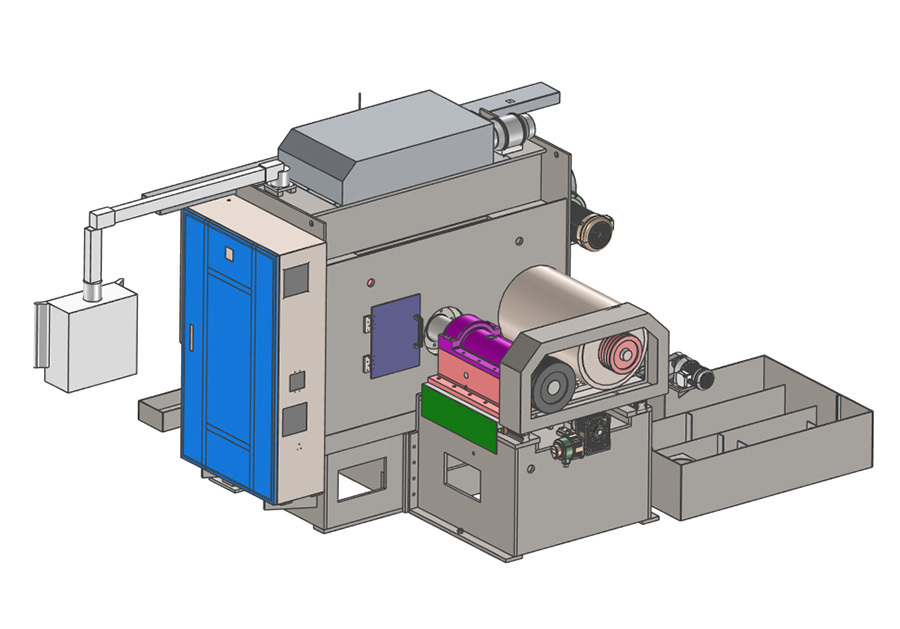

Durable Spindle Box

The spindle box is cast in upper and lower parts for easy installation and maintenance.The spindle adopts an integral forging process, which has higher durability and stability, longer service life and more reasonable lubrication.

Intelligent Control

The servo motor feeds fullyautomatically, the feeding position is accurate, andthe feeding frequency can be intelligently adiustedin real time according to the setting of main motorcurrent.

Complete Functions

The equipment consists of an exhaust, a universal adjustable water spray device, a sand and gravel sedimentation device, magnetting machine and an air blowing and cleaning device, etc.

Specification Parameters

| Equipment Model | HX-60 | HX-90 |

| Spring material diameter | 15~40mm | 20~65mm |

| Spring outer diameter | 60~260mm | 100~400mm |

| Spring maximum length | 600mm | 1000mm |

| Grinding wheel motor power | 22kw | 37kW |

| Grinding Wheel Size | Ф 600*Ф 300*100mm | Ф 900*Ф 460*100mm |

| Grinding Wheel Speed | 1100RPM | 735RPM |

Related Products

Graphic Details

Product Consulting

Graphic Details