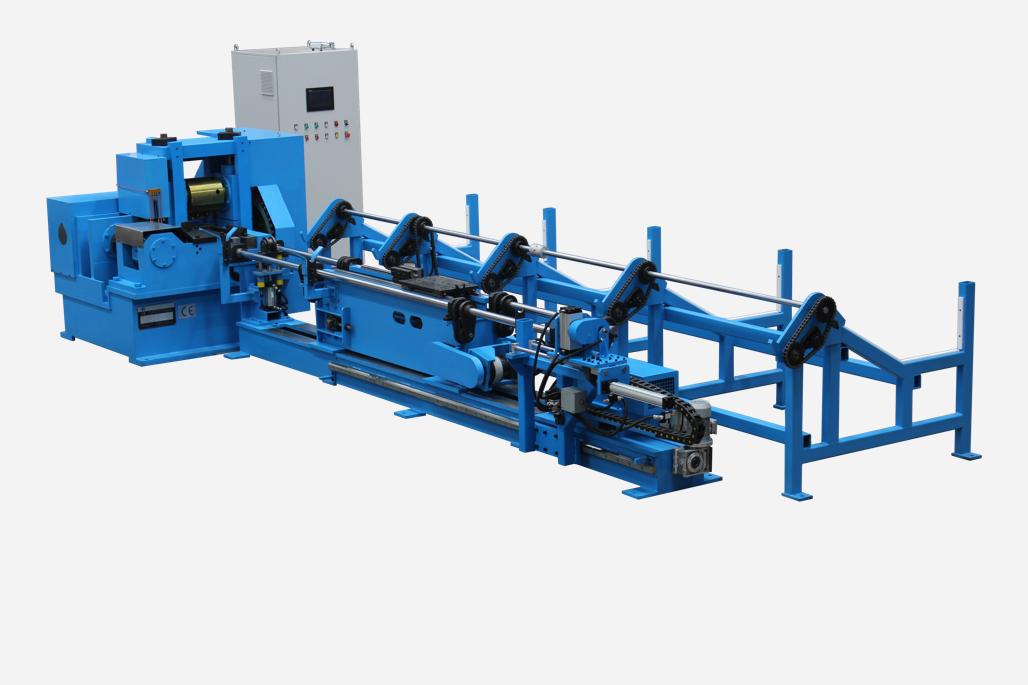

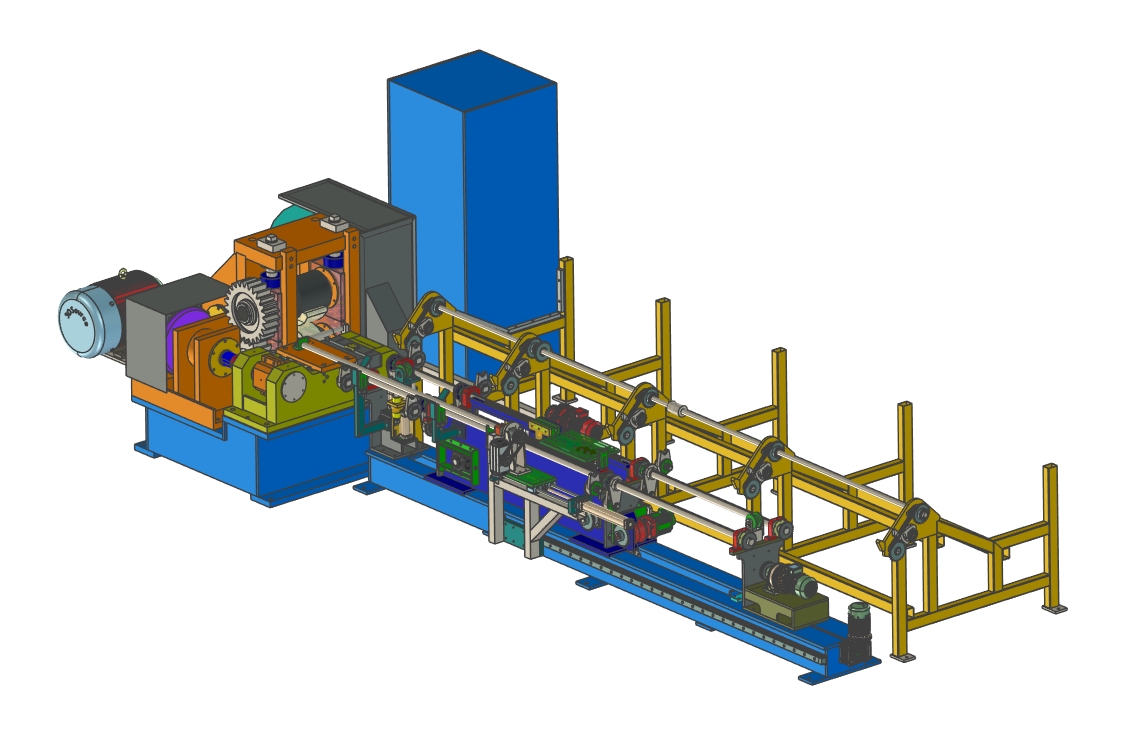

Mechanical Flattening Machine

This equipment is mainly used for the two ends of the bar flattening, it uses the roll eccentric method to produce the required taper of the bar, the upper and lower rollers run synchronously, and symmetrically, and the rolling taper surface is symmetrical; the mold can be adjusted on the equipment to control the thickness and width of roling material and the flattening length and flattening taper can be adjusted.

Key words:

Classification:

Email:sxjkzdh@163.com

Detailed introduction

Graphic Details

Equipment Introduction

This equipment is mainly used for the two ends of the bar flattening, it uses the roll eccentric method to produce the required taper of the bar, the upper and lower rollers run synchronously, and symmetrically, and the rolling taper surface is symmetrical; the mold can be adjusted on the equipment to control the thickness and width of roling material and the flattening length and flattening taper can be adjusted. The rollers are made of wear-resistant materials which have long service and standard size, it is easy to replace. The automatic feeding mechanism can move the heated material into the clamping mechanism and feed it into the roller through the servo motor. After completing the rolling, it exits and completes the width direction forming in the side extrusion device below. The rolling is completed process after several cycles. lt is the best choice for small specifications and large batches because of its good product consistency, high production efficiency, high degree of automation and simple operation.

Functional Advantages

Unmanned Production

The flattening machine is equipped with automatic feeding and automatic feeding manipulators, which can realize material positioning, lateral movement, automatic clamping material lifting, servo feeding and other functions, which enables fully automatic production.

Good Product Consistency

The flat taper of the product is completed by an adjusted fixed mold, the production process is consistent, the material taper is also highly consistent, and the maximum thickness deviation is 0.5mm.

High Production Efficiency

The manipulator is fully automated for production, continuous and efficient, and the material translation can realize simultaneous loading and unloading. The fastest production cycle can reach 15S.

Convenient Specification Adjustment

The equipment mold is made of high-temperature and wear-resistant materials, the flat taper is adjusted through a semicircular eccentric structure. One mold can be compatible with all flat tapers.

Specification Parameters

| Equipment Model | PY-40 |

| Material diameter | 20-40mm |

| Flattening length | ≤ 350mm |

| Total length of flat material | 2000-4000mm |

| Minimum end thickness | 5mm |

| Side squeezed parts | 20mm |

| Rolling temperature | >=1000℃ |

| Product unit cycle time | 20s/(piece) |

| Main motor power | 30kw |

| Feed motor power | 3kw |

| Roll speed | 42r/min |

| Equipment weight | 10-11t |

Previous:

Related Products

Graphic Details

Product Consulting

Graphic Details