28

2022

-

07

Overview and Characteristics Analysis of Spring-Type Production Line Equipment Models

The 3D models provided in this article are mostly modeled using mechanical drawing software such as SolidWorks, Proe/Creo, UG/NX, CATIA, and Inventor. Please note that some models may not include the source format files, but we will provide common intermediate formats such as step, igs, stl, and bin to ensure that you can smoothly preview and use these models.

About the use and preview of 3D models:

The 3D models provided in this article are mostly modeled using mechanical drawing software such as SolidWorks, Proe/Creo, UG/NX, CATIA, and Inventor. Please note that some models may not include source format files, but we will provide common intermediate formats such as step, igs, stl, and bin to ensure you can smoothly preview and use these models.

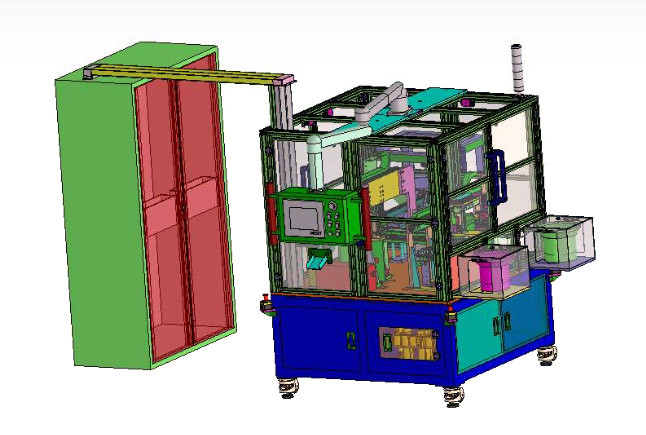

Below is an overview of the preview images of various 3D models:

The non-standard automation spring production line equipment model is designed to meet specific production needs with a flexible and adaptable automated production line. Compared to traditional standardized production lines, it is better suited for producing springs of various specifications and materials. This model takes into full account all aspects of spring production, from raw material transportation, processing and forming to quality inspection and finished product packaging, achieving automation and significantly enhancing production efficiency.

In terms of structural design, this production line adopts a modular design, allowing each functional module to operate independently while being flexibly combined to meet the needs of different production scales. At the same time, this design also simplifies equipment maintenance and management, reducing operating costs.

In terms of automation control, the production line is equipped with an advanced PLC system to achieve precise control over equipment operation. Through programming and debugging, the production process can be easily managed, including speed control, quality inspection, and data recording, which improves efficiency and ensures quality stability.

In addition, the production line is also equipped with safety protection devices to ensure the safety of operators. At the same time, the application of energy-saving and environmentally friendly concepts has reduced energy consumption and emissions after optimizing the structure and control system, achieving green production.

In the field of spring production, this equipment model has a wide range of applications. Whether in automotive, electrical appliances, or industrial equipment, spring components can be efficiently produced through this production line. Its high degree of automation and flexibility also allows for quick switching to produce springs of different specifications and materials, meeting the diverse needs of the market.

Additionally, this equipment model also has good scalability and upgradability. With the advancement of production technology and changes in market demand, the equipment can adapt to new production needs through upgrades and modifications, ensuring long-term use and investment value.

In terms of maintenance and management, this equipment model also demonstrates excellent performance. Its functional modules follow standardized design concepts, allowing maintenance personnel to quickly and accurately locate and resolve potential faults. In addition, the equipment is equipped with an intelligent fault diagnosis system that can monitor the operating status of the equipment in real-time and issue early warnings of faults, effectively reducing the impact of equipment failures on the production process.

In summary, the non-standard automation spring production line equipment model not only excels in production efficiency and quality but also demonstrates its unique advantages in maintenance management and technological upgrades. Its widespread application will undoubtedly drive the spring production industry towards greater efficiency, higher quality, and safer, more environmentally friendly practices.

Key words:

Related News

Coil Spring Machine: Ushering in a New Chapter of Industrial Innovation

2025-11-20

New Developments in the CNC Thermal Rolling Industry: Technological Innovation and Market Trends

2025-11-05