JINKONGKEJI

Dedicated to hot-rolled spring equipment

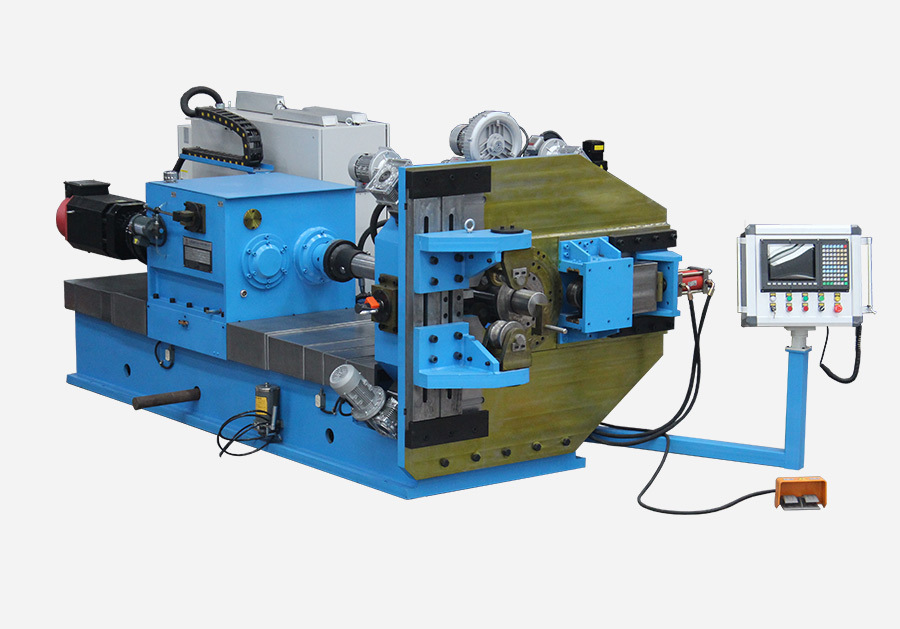

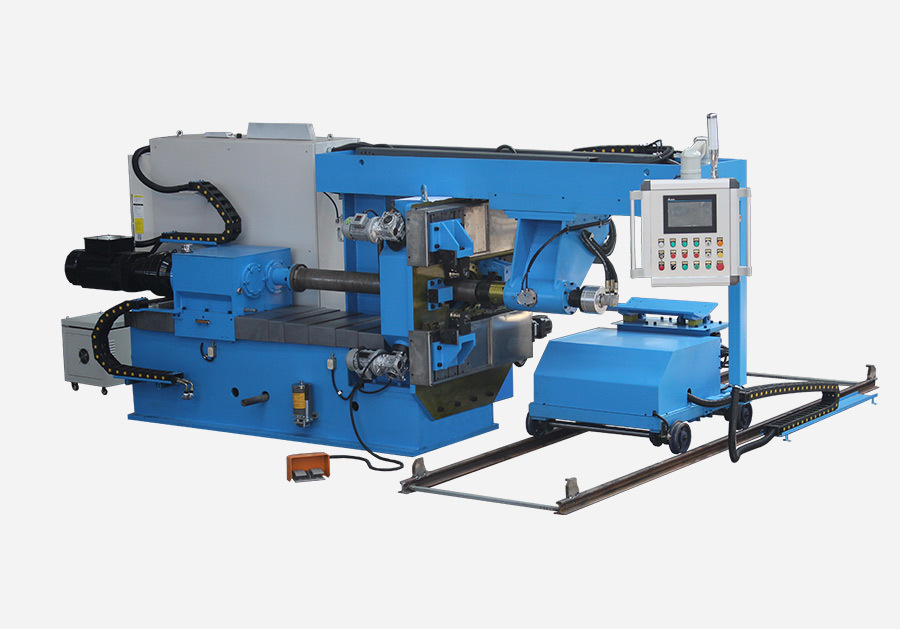

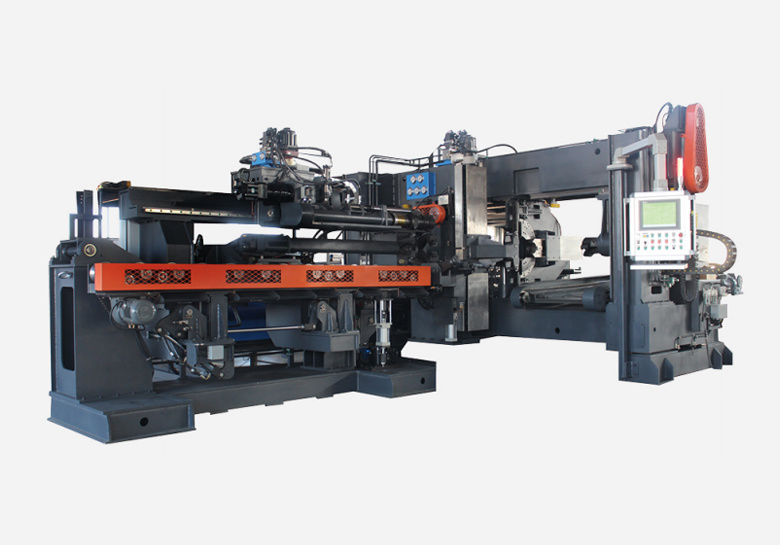

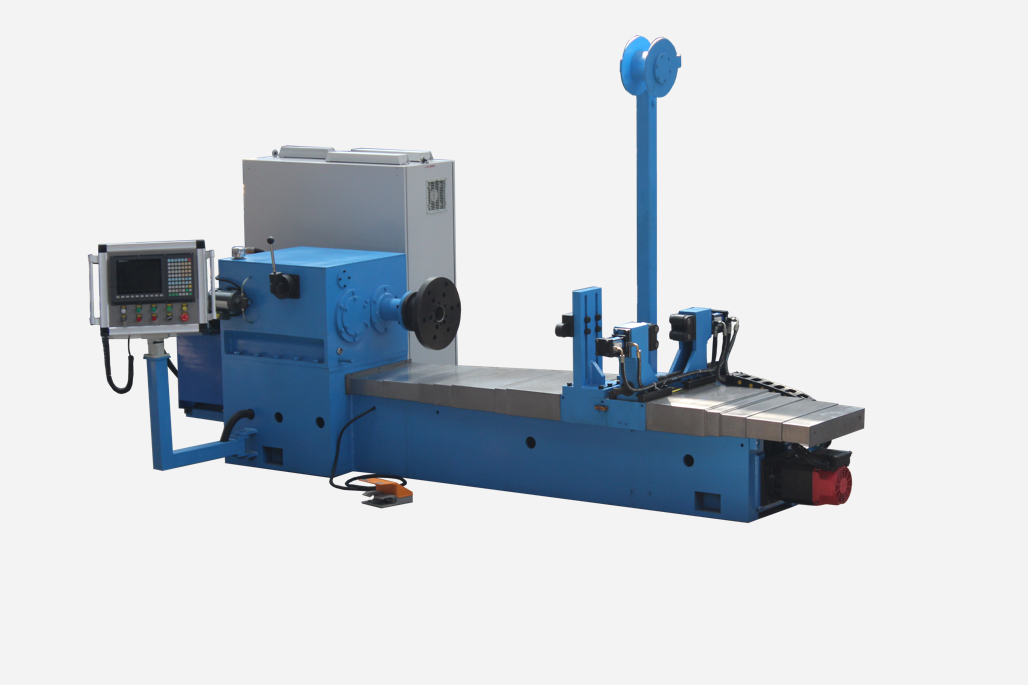

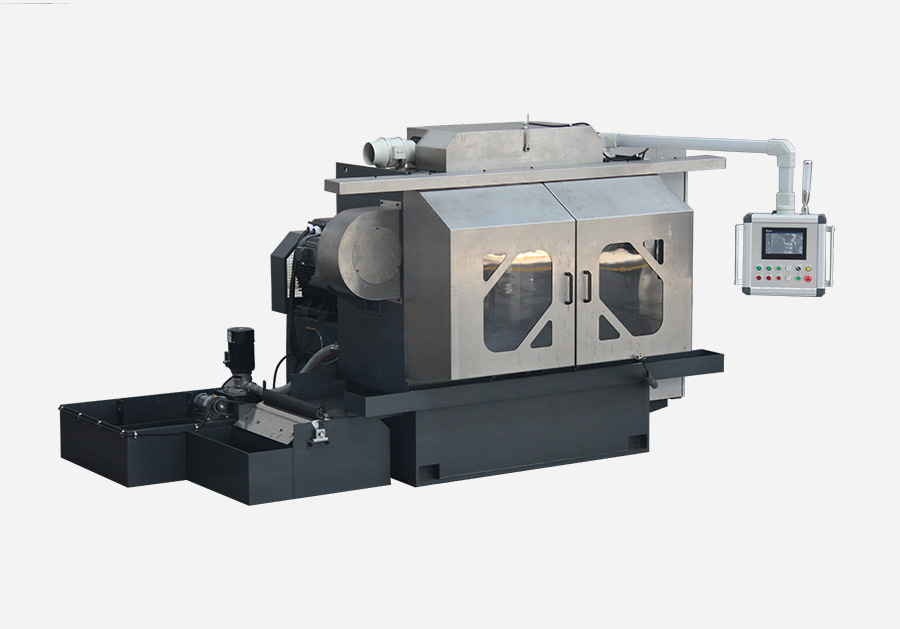

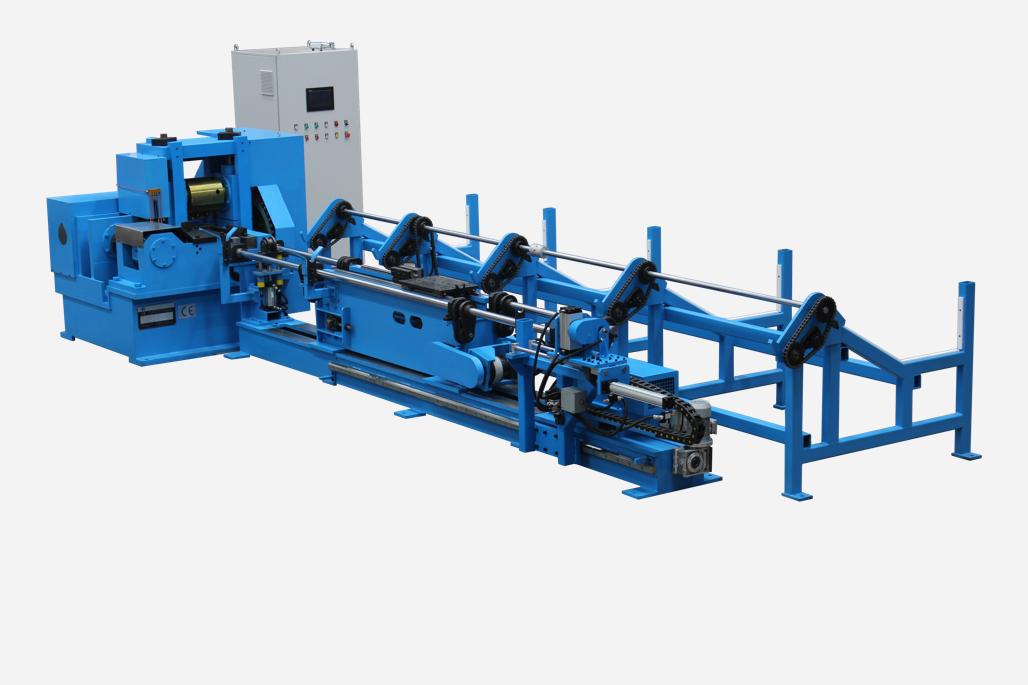

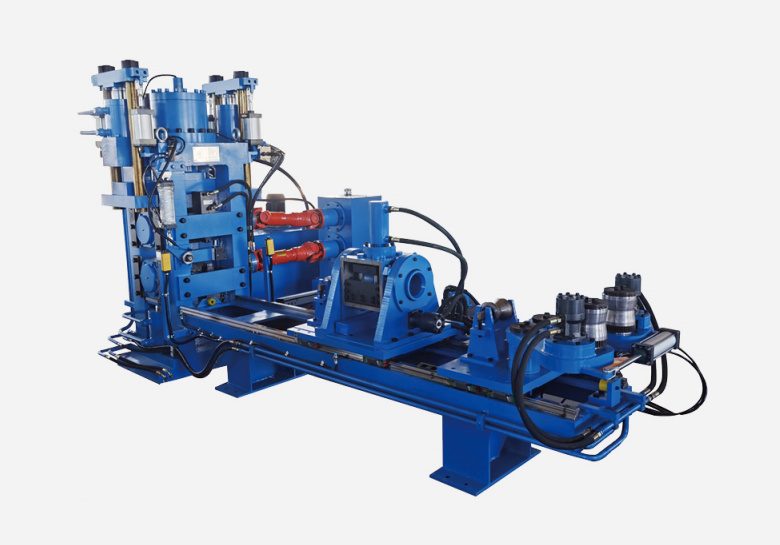

Mainly produces hot-rolled spring machines, flattening machines, spring grinding machines, etc., as well as a complete set of hot-rolled spring automation production lines. The CNC fully automatic hydraulic flattening machine and CNC spring grinding machine have obtained multiple national patents.

MORE